.png?sfvrsn=1b6bae1a_0) (FASTER)

(FASTER).png?sfvrsn=ac211bda_0)

Accurate, real-time water-cut measurements are critical in the oil industry for production monitoring and management. Traditional methods often require calibration specific to each well, which is time-consuming and inefficient. Our sensor addresses these challenges by providing a fast, non-intrusive, and calibration-free solution.

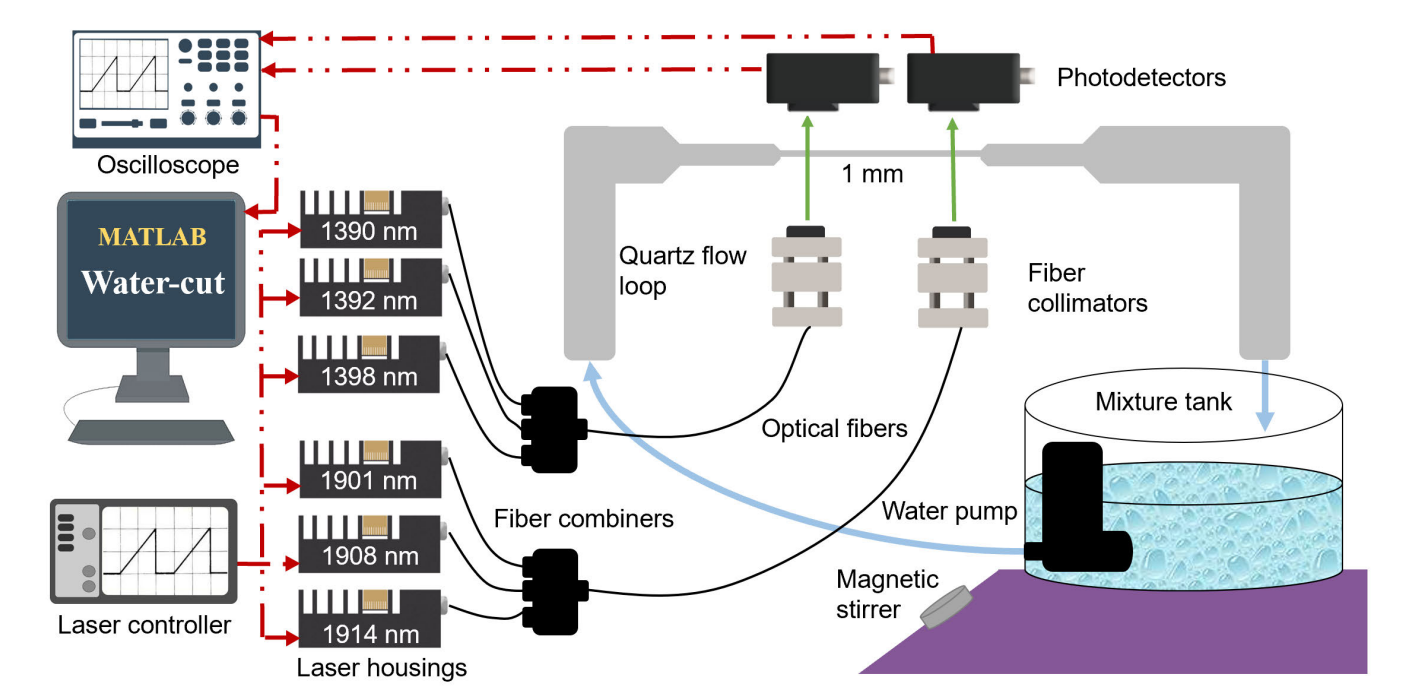

Optical schematic of the water sensor setup

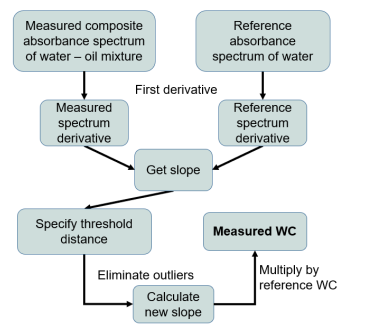

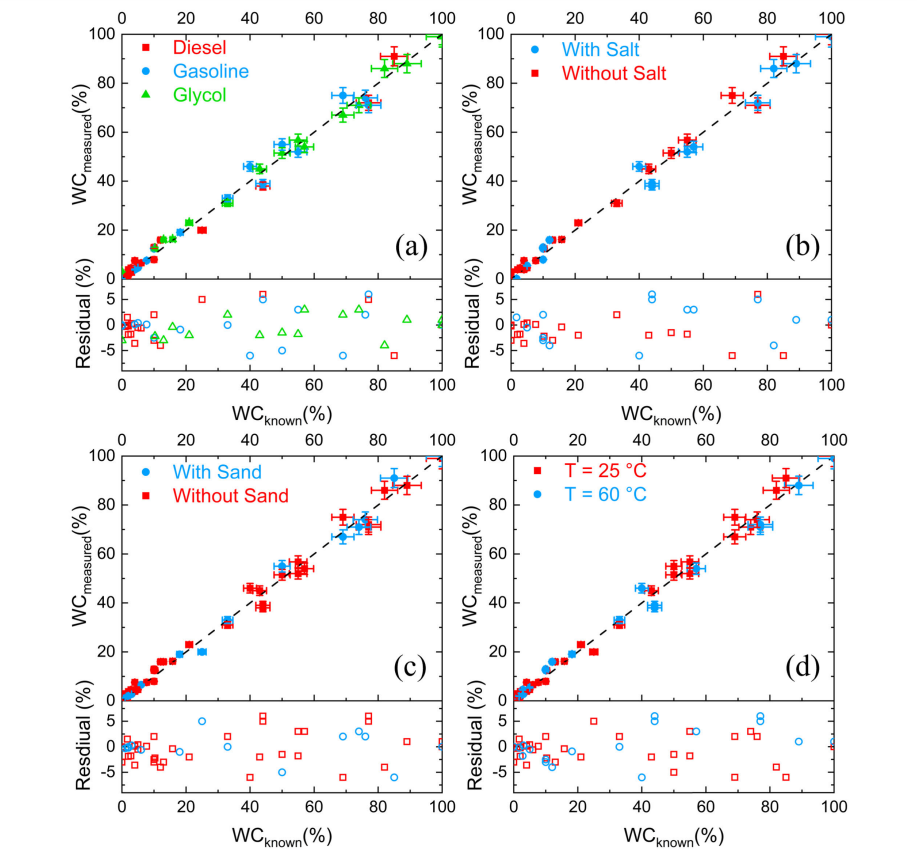

The sensor operates by probing water absorption lines near 5000 cm⁻¹ for low water cuts (0%–10%) and 7000 cm⁻¹ for high water cuts (10%–100%). It uses a gradient-based algorithm to distinguish between water and oil, without needing well-specific calibration. The system was validated using a benchtop flow-loop with oil substitutes (glycol, diesel, gasoline) and demonstrated high accuracy (±5% absolute, 95th percentile). It is immune to the presence of salt, sand, and temperature.

Overall algorithm used to retrieve water-cut from the measured spectra

Impacts:

EXPEC Advanced Research Center, Saudi Aramco

Patents