.png?sfvrsn=1b6bae1a_0) (FASTER)

(FASTER).png?sfvrsn=ac211bda_0)

The motivation for this project arises from the limitations of diaphragm-based shock tubes, such as long setup times, debris contamination, and inconsistent results. Diaphragmless shock tubes offer cleaner operation and faster experimental cycles, which are crucial for high-repetition-rate research in fields like combustion, aerospace, and materials testing.

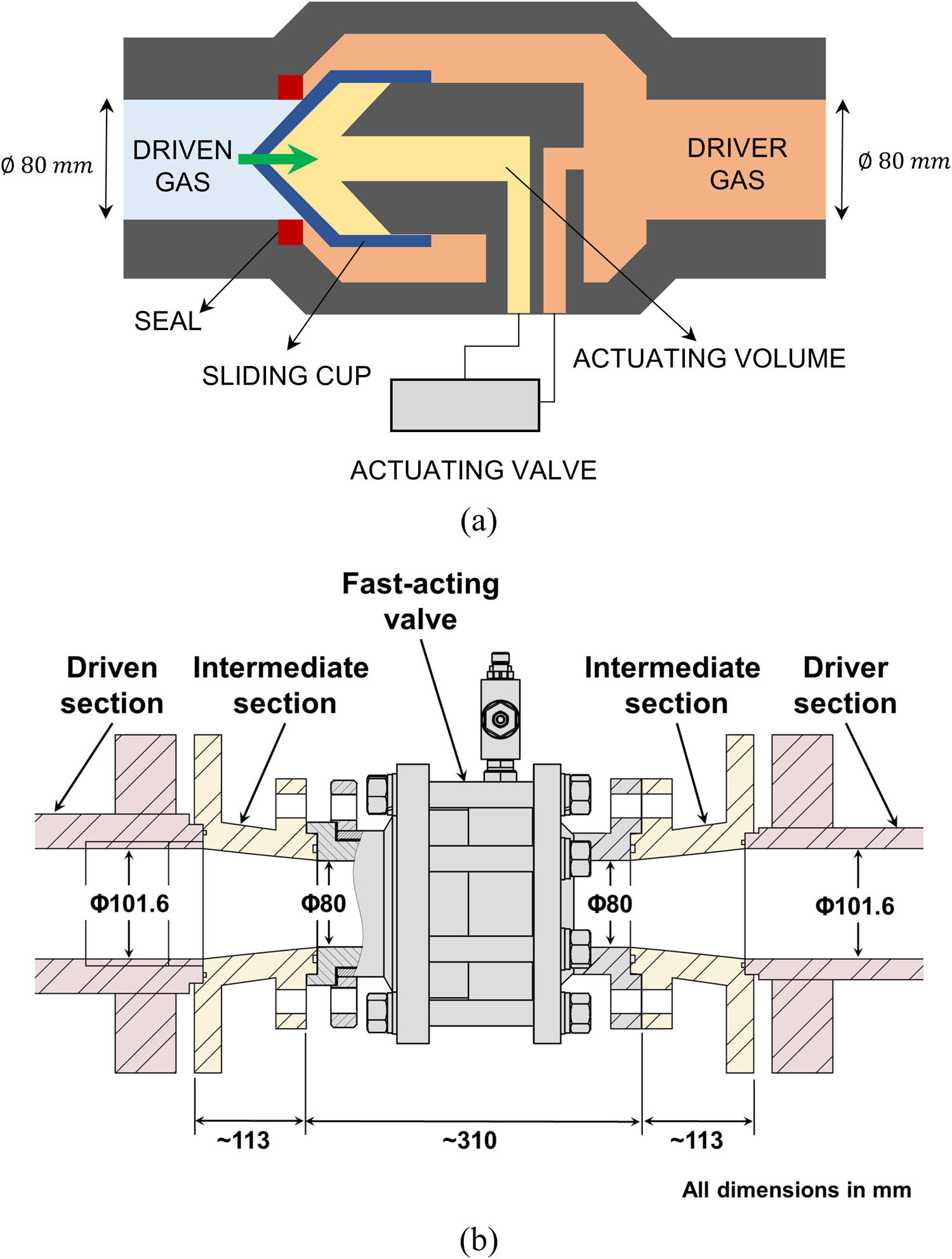

Schematic diagram showing the internal flow path and major components of the fast-acting valve.

Diaphragmless shock tubes are designed to replace conventional diaphragm-bursting methods with fast-acting valves, offering several advantages. These include quicker experimental turnaround times, better repeatability, and the elimination of diaphragm debris. The project reviews various valve designs, actuation mechanisms, and driver-driven configurations to determine optimal performance across a wide range of research applications, from chemical kinetics to materials science.

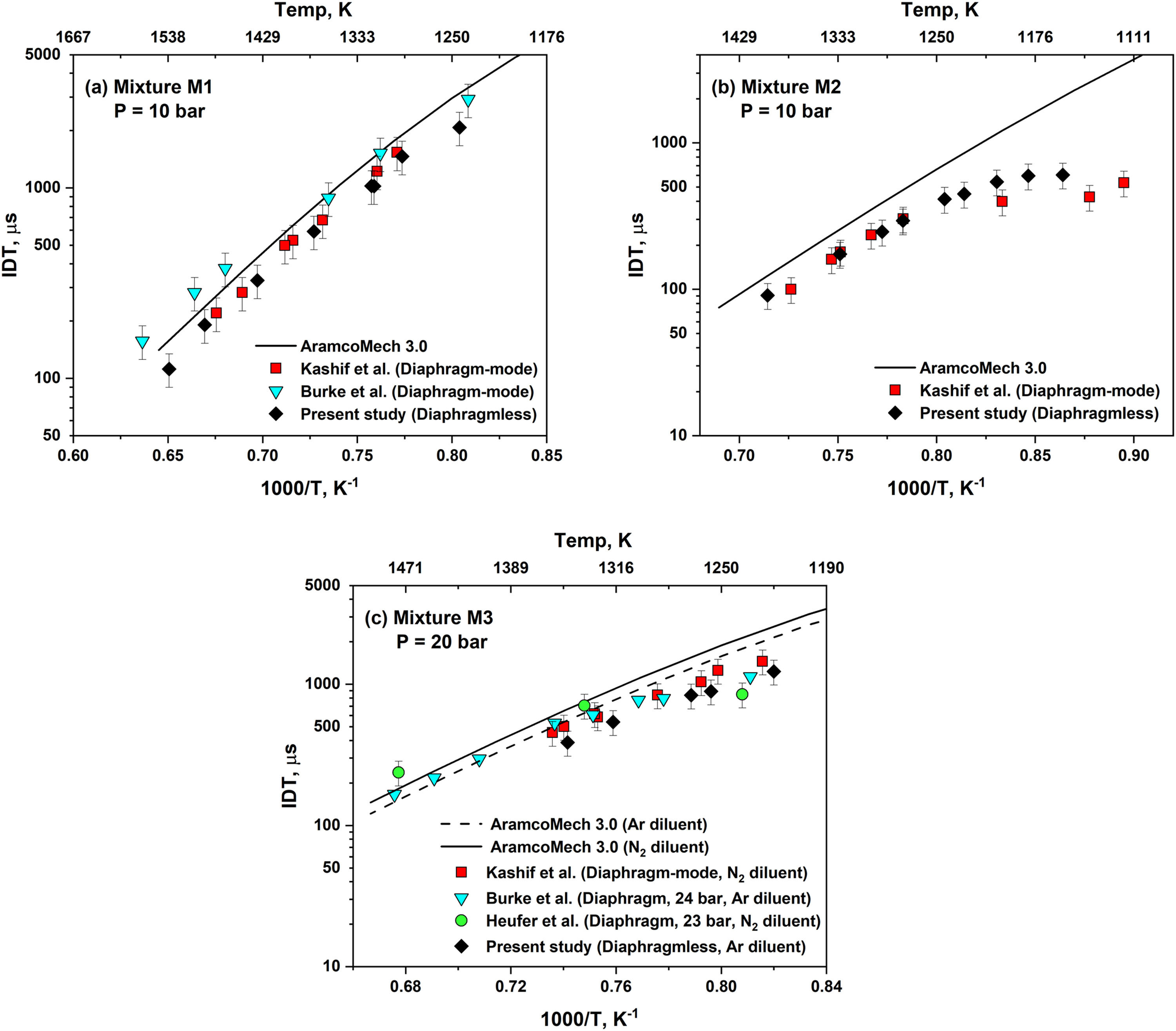

Comparison of IDT measurements in the diaphragmless- and diaphragm-mode for methane mixtures

Impacts: