.png?sfvrsn=1b6bae1a_0) (FASTER)

(FASTER).png?sfvrsn=ac211bda_0)

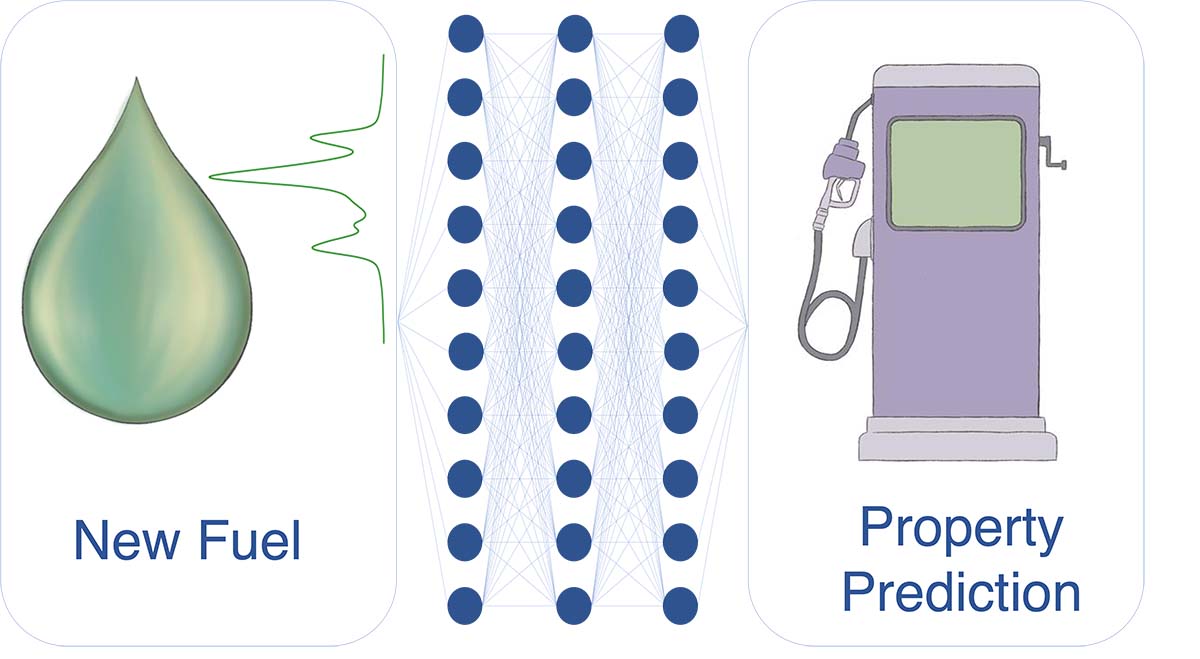

With many new alternative fuels being proposed from bio/synthetic routes, it is important to develop tools for accurate and efficient fuel screening and fuel blending methods. The quality of gasoline fuels is usually measured by their anti-knock capability through octane number indicators which require a Cooperative Fuel Research (CFR) engine. Similarly, the quality of diesel fuels is given by their ignition tendency and quantified by the cetane number which also requires a CFR engine or an Ignition Quality Tester (IQT) for the alternative Derived Cetane Number (DCN). Running these experimental tests is costly, time consuming, and cumbersome. Many efforts have been made to develop accurate mathematical and chemometric techniques for quick and accurate predictions. We propose the application of machine learning methods on simulated spectra of hydrocarbon blends and real fuels.

We demonstrate that simulated spectra based on the linear-by-mole summation for blends and the PIONA class-averaged approximation for real fuels retain important information needed for prediction of global properties. The study sheds light on the significance of dimensional reduction of spectra and shows how it can be used to extract scores with linear correlations to the following important features: molecular weight, paraffinic CH3 groups, paraffinic CH2 groups, paraffinic CH groups, olefinic −CH═CH2 groups, naphthenic CH–CH2 groups, aromatic C–CH groups, ethanolic OH groups, and branching index. Three models were applied to the spectra: Partial Least Square (PLSR – standard method in chemometrics), Support Vector Machines (SVM), and Artificial Neural Networks (ANN). Our ANN models provided the best predictions with mean absolute errors within experimental uncertainty for Research Octane Number (RON), Motor Octane Number (MON), Octane Sensitivity (OS), Derived Cetane Number (DCN), and Carbon/Hydrogen ratio. The model was initially developed for gasoline-like fuels (Al Ibrahim & Farooq, 2020) and then the framework was later on generalized to apply to diesel-like fuels (Al Ibrahim & Farooq, 2021).

In addition, we have recently utilized CFD and ML approaches to optimize the combustion system of a light-duty GCI engine. Here, a Machine Learning-Grid Gradient Algorithm (ML-GGA) approach was developed to optimize the piston bowl design. This optimization exercise yielded significant improvements in the engine performance and emissions compared to the baseline engine designs.